Cabinets Don’t Run Clinics: Quiet Gaps To Close Early

Product: Color Method

Brand: Color Method

Topic: Dental Procedure Efficiency | Dental Products | Color Method

October 17, 2025

The Quiet Gap Smart Equipment Specialists Close Early

You’re one of the first calls when a dentist decides to build. You help shape the vision, juggle vendors, and guide thousands of dollars in cabinetry and equipment decisions. But there’s a quiet pattern we see over and over: workflow gets solved after the cabinets are already on order.

That’s when the problems surface: drawers that don’t fit what the team actually uses, sterilization that backtracks, storage that looks full but functions empty. Beautiful specs… clunky days.

And when the practice feels “off,” it doesn’t fall back on the architect. It falls back on you and the FSCs.

What Equipment Specialists Already Own

(and what gets blamed on you anyway)

You shepherd vision, vendors, and big-ticket decisions. But once the doors open, the team doesn’t judge by drawers and finishes. They judge by how the day runs:

- Are assistants leaving ops mid-procedure?

- Do instruments move from dirty to clean without backtracking?

- Is storage sized for actual procedure volume or for "just in case"?

When those answers are fuzzy, the frustration rolls uphill to the person who led the build.

The Inch That Costs You Every Day

One recent project had a base unit in central sterilization just one inch too narrow. That inch meant no room for double trays. The result? A second setup station across the hall and a daily back-and-forth that never should have been built in. Small miss, permanent tax = a clinical team who silently wonder, “Who designed this?”

One inch doesn’t sound like much on paper. In real life, it’s a permanent inefficiency the client feels every single day.

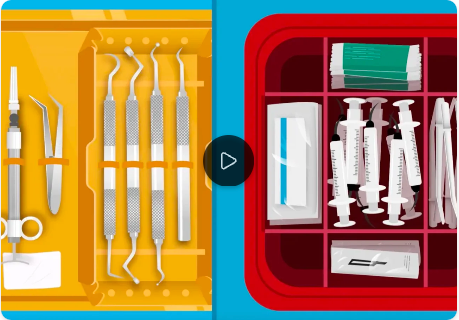

The Swap That Changes Everything

In another project, the original plan placed sterilization and the lab side by side—but chopped into awkward, disconnected zones that would become the cabinet maker’s mess.

By simply swapping the two spaces, the dirty side of sterilization could flow straight into clean storage, with a full 17-foot run of cabinets to stage trays and tubs. The lab moved into the awkward room, but had far more flexibility with countertops and workstations.

One shift. Same square footage.

But the daily experience for the team will be completely different: ample clean storage, bulk storage tucked in logically, and clear clean/dirty workflows in sterilization. Watch the whole video here.

Where Zirc Fits

(with you, not instead of you)

Zirc isn’t here to compete with your scope. We’re here to close the gap between how a practice looks and how it runs once the doors open.

- Floor plan review: we spot the choppiness that makes sterilization clumsy.

- Cabinetry spec: we plan what actually goes where—so you’re not paying for dead drawers.

- Training & go-live: we map tubs, trays, and storage zones so the team uses the system from day one.

The framework behind it—Color Method—standardizes instruments and materials by procedure. It turns “where does this go?” into instant recognition. For you, that means fewer callbacks, faster buy-in, and a practice that feels dialed in the moment it opens.

This is the operating system that prevents “beautiful but clunky.”

What’s In It For You

Bringing Zirc in early does three things for an equipment specialist:

- Protects your reputation. Clients experience smooth days, not hidden flaws.

- Strengthens your sale. Cabinetry decisions are backed by workflow logic, not guesswork.

- Reduces rework. The build feels finished, not like it needs fixing.

You already own the equipment side. We make sure the clinical side performs.

The Bottom Line

The difference between “great cabinets” and “great practice flow” is small—but clients feel it immediately.

Add Zirc to your early process, and that one inch, that one drawer, that one overlooked flow doesn’t come back to haunt you. Instead, you’re remembered as the partner who thought of everything.

Clinical efficiency is all the difference in 2025 and beyond.